In the world of high-performance motion control, precision, flexibility, and speed are non-negotiable. ACS Motion Control’s proprietary programming language, ACSPL+, delivers all three—empowering OEMs and machine builders to develop sophisticated motion applications with unmatched efficiency.

What Is ACSPL+?

ACSPL+ is a powerful real-time programming language designed specifically for motion control systems. It supports up to 128 axes, executes programs at rates up to 10 kHz, and enables multi-tasking across 64 simultaneous buffers. Whether you’re building semiconductor inspection systems, laser micromachining platforms, or precision biomedical equipment, ACSPL+ provides the tools to meet demanding application requirements.

Key Features & Benefits of ACSPL+

1. Real-Time Performance > Maximize Throughput

ACSPL+ executes motion control code at up to 10 kHz in up to 64 multi-tasked buffers. This enables machine designers to coordinate motion with real-world events and software user interfaces to maximize machine throughput and system responsiveness.

2. Advanced Programming Capabilities > Flexibility to Scale

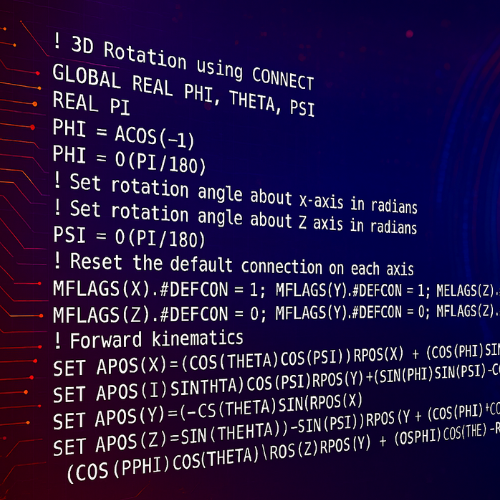

- Combines object-oriented and scripting for powerful yet intuitive development.

- Supports user-defined functions in standard C for real-time execution.

- Includes algebra functions for kinematics and data processing.

3. Robust Controller Simulation Environment > Reduced Development Time

Develop and debug applications using a full controller simulator that emulates motion, I/O, events, & other logic. This allows engineers to develop entire motion systems without hardware dependencies significantly reducing development time and allowing machine builders to bring next-generation equipment platforms to market faster.

4. Comprehensive & Backward Compatible > Re-usable Code Base

ACSPL+ includes a comprehensive command set for any and all motion control and machine control functions. Its continuous evolution over 25+ years ensures long-term stability and compatibility—no code rewrites required. Command set highlights:

- Axis management

- Advanced motion profiles: MotionBoost, SmoothPath & more

- Motion-to-Event Synchronization: PEG, MARK, Position event generation (PEG)

- Advanced Servo Control algorithms

- and many more

5. High-Speed Data Collection > Improve Process Control

With Servo Processor Data Collection (SPDC), ACSPL+ enables fast sampling (up to 20 kHz) of critical motion system variables to machine events and improve process control.

6. Diagnostics and Preventive Maintenance > Reduce Downtime

Built-in tools help identify undesirable behaviors and generate maintenance indicators—reducing downtime and extending equipment life.

7. Password Protected > Secure IP Protection

Secure your application code and machine settings with password protection, ensuring safe access for developers and operators.

8. Seamless Integration with Host Applications > Programming Flexibility

ACSPL+ works seamlessly with host programming libraries across platforms including C/C++, .NET, Python, MATLAB, Linux, and MacOS. This flexibility allows engineers to integrate motion control functionality into broader machine architectures with ease.

ACSPL+: Designed for Precision Motion Control Systems

From laser processing to semiconductor metrology, ACSPL+ is engineered to handle complex, multi-axis motion with precision and reliability. Its continuous evolution over 25+ years ensures long-term stability, compatibility and a re-usable code base to quickly develop new advanced automation equipment.